PRODUCT

product2

首页>PRODUCT > Heat Release Rate>FIPEC wire and cable heat release rate tester

首页>PRODUCT > Heat Release Rate>FIPEC wire and cable heat release rate tester

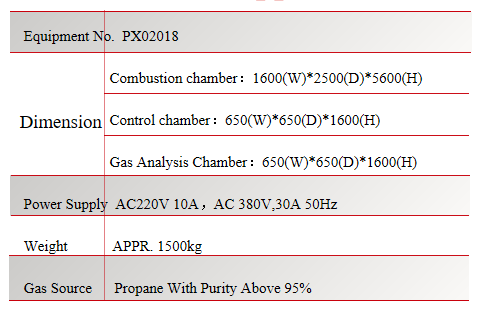

产品型号:PX02018

标准编号:EN50399

应用领域:

检测目的: Heat Release Rate

Heat Release Rate

行业标准:

EN European standard

EN European standard

This standard specifies the test apparatus and test method for evaluating the flame spread, heat release and smoke production characteristics of vertically mounted bunches of wire and cable or optical cable under specific test conditions. The experiment can obtain the flame spread (FS), heat release rate (HRR), total heat release (THR), smoke production rate (SPR), total smoke production (TSP), combustion growth rate index (FIGRA), and combustion droplets/particulates under specific combustion conditions

GB/T 31248-2014 Characteristics of flame spread, heat release and smoke generation of cables or optical cables under fire conditions

EN 50399 Cables - Heat release and smoke generation characteristics for flame propagation tests

Steel structure combustion chamber, inner wall is stainless steel plate, filled with mineral wool insulation

The front end of the combustion chamber is equipped with an open and sealed steel door with fire-resistant toughened glass observation window

Independent electric control cabinet, convenient site layout arrangement

Belt propane burner burner with imported Venturi mixer

Equipped with high-precision MFC to control gas and air feed, and through venturi mixing, the burner can provide a stable fire source

Equipped with silicon nitride ignition device, ignition stable and reliable.

Flameout automatic degase protection device, programmable controller (PLC)+ MFC to achieve automatic control of ignition and flameout propane and air supply sequence

Equipped with stainless steel movable trolley, used for placing and adjusting the test position of blowtorch, easy to use

In the air supply section, adjustable speed blower and frequency converter are used to control the air inlet velocity, and the air inlet volume is measured by pitot tube and differential pressure sensor.

The upper part of the test chamber is equipped with pitot tube and differential pressure sensor for wind speed measurement to ensure the test wind speed.

The stainless steel air collecting hood is installed above the experimental box, the diameter of the stainless steel exhaust duct is 400mm, and the flow equalizer device is used before and after the exhaust pipe to make the gas flow evenly.

Equipped with high temperature fan, smoke exhaust capacity is not less than 1.5m³/S. The smoke exhaust fan can be adjusted to ensure that the hood can collect all the smoke; The accuracy of flue gas flowmeter is not less than ±5%, and the response time is not more than 1s

Equipped with 4 imported thermocouples to monitor the temperature in the exhaust pipe, the measurement accuracy is ±0.1℃

Thermocouple and pipe sleeve connection, convenient disassembly and processing

Equipped with stainless steel two-way probe to measure the wind pressure in the smoke tube, the two ends of the control head are respectively facing the windward and leeward side of the smoke

Equipped with imported differential pressure transmitter to convert pressure signal and output

Equipped with imported light source with color temperature of 2900K, the light source is converted into parallel light beam through the smoke tube through lens device and focal length adjustment device

The imported silicon optical receiver will transform the optical signal changes into electrical signals and output them, the data is stable and accurate

Equipped with standard filter for optical path system calibration

The sampling probe is installed in the sampling pipe of the equipment. The sampling probe is made of stainless steel, which is connected with the sampling pipe through a flange or thread structure and is fixed and sealed. A row of small holes are arranged in the center of one side of the sampling probe for sampling, and the sampling holes are away from the direction of wind speed flow to prevent the blockage of combustion dust

The sampling probe is connected to the sampling pump through the PP hose to pump the sampling gas to the gas pretreatment system. The sampling pump pumping volume is 36L/Min, working pressure 7Kg pressure (0.7mpa) working vacuum degree -93.1kpa, flow rate 36L/Min

The gas pretreatment system includes filtration system, gas cooling system, gas dehumidification and drying system and gas regulation system.

Equipped with a three-stage filter system, the first-stage filter is a cylindrical coarse filter system, used to filter the relatively large particles in the flue gas, prevent the blockage of pipes and joints, the filter can be replaced. The secondary filter adopts cup type protection filter, which can filter particles larger than 0.5μm. The filter element device can be replaced. The three-stage filter adopts membrane filter to filter particles larger than 0.2μm.

The cooling system is condensed and dehydrated by condenser and peristaltic pump. The condenser has dual cooling, the stable dew point temperature is about 0.1℃, the outlet temperature is about 5℃. The outlet of peristaltic pump is equipped with condensate collecting box with built-in sponge.

The dehumidification and drying system uses the air filter tube to place DRIERITE brand anhydrous calcium sulfate for dewatering treatment, and filters the gas moisture to be measured in the air pipe to ensure the drying of the gas entering the analyzer. Anhydrous calcium sulfate can change color after absorbing water, easy observation and easy replacement.

Analysis/calibration switch unit: analyze the cabinet panel has sample gas inlet, standard gas inlet quick plug, and adopts high reliability ball valve, three-way switch valve, easy to field adjustment and maintenance.

Fast bypass: It is equipped with Devere rotor flowmeter for sample gas bypass discharge. The flowmeter is mounted on a panel to ensure that the sample gas flow into the analyzer is 3.5L/Min.

Pressure regulating device: the pressure regulating valve is used to adjust the pressure, and the pressure of the regulating valve can be adjusted from 0 to 0.4mpa.

Professional HRR test gas analyzer, including O₂, CO₂

O₂ : paramagnetic sensor, range 0-25%, accuracy 0.02%, response time T90< 7s

CO₂ : infrared sensor, range 0-10%, accuracy 1%F.s, response time T90< 8S

Support analog output and Modbus RTU and other transmission modes

Computer + professional software control, can guide the experimental process, easy to operate, safe and reliable

Automatic measurement and calculation of material combustion heat release rate (H.R.R), smoke production rate (SPR), oxygen consumption,O₂,CO₂ generation; It can collect and save various data. Screen monitoring and test data can be realized